Australia Wide Shipping

Australia Wide Shipping

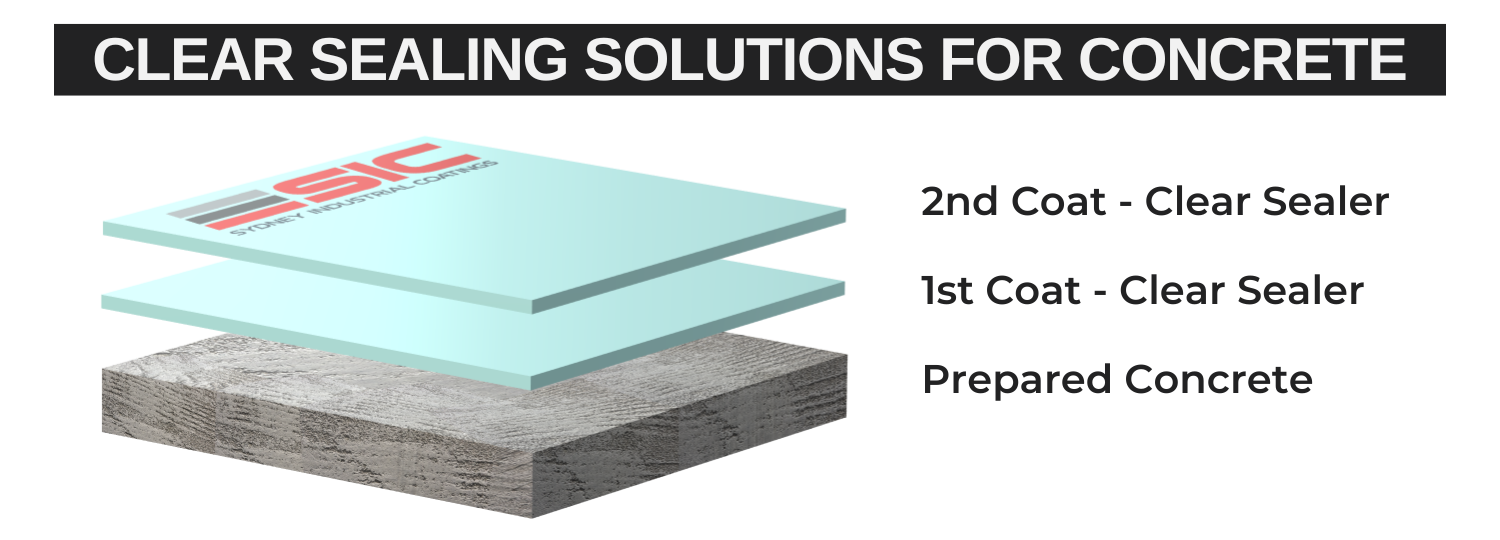

Clear concrete sealers and polyurethane finishes are products that are used to protect and enhance the appearance of concrete surfaces. They are applied as a clear liquid and are designed to seal and protect concrete from moisture, stains, and other types of damage. There are many different types of clear concrete sealers available, including penetrating sealers, topical sealers, and others..

Penetrating sealers

These are clear sealers that penetrate into the concrete to provide a protective barrier against moisture and other types of damage. They are often used on outdoor surfaces like driveways, patios, and sidewalks, and help to prevent cracking, staining, and spalling. They are typically low-VOC and breathable, meaning that they do not form a surface film on top of the concrete, which can trap moisture.

Topical sealers

These sealers sit on the surface of the concrete to provide a protective barrier. They can provide a glossy or matte finish, they can enhance the color of the concrete, or they can be used to add slip resistance. They are often used in indoor or high-traffic areas, such as on concrete flooring in commercial or industrial buildings.

Polyurethanes

Polyurethanes are clear coatings that are often used as a topcoat over concrete floors, they are typically used in commercial or industrial setting to protect the concrete from heavy traffic and wear. They can be also used as sealers and can be applied as both penetrating or topical. They are known for their exceptional durability, chemical resistance and flexibility. They are also resistant to UV light and chalking, which means they maintain their clarity and durability over time.

It is important to note that, before applying a clear concrete sealer, the concrete surface should be clean, dry, and free of any contaminants such as oil, grease, or dirt, as this can affect the performance of the sealer. Additionally, depending on the type of sealer, more than one coat may be necessary for optimal protection and performance.

Showing all 4 results